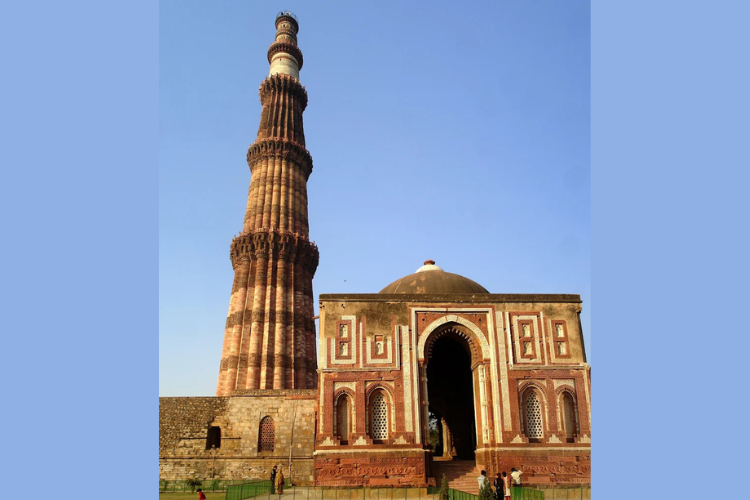

Standing tall amidst the Qutub Minar complex in Delhi, India, is an ancient marvel that continues to baffle scientists and metallurgists worldwide: the Iron Pillar. This imposing structure, nearly 7.2 meters (23 feet 8 inches) high and weighing over six tons, has stood exposed to the elements for over 1,600 years, yet shows astonishingly little sign of rust.

How did ancient Indian artisans achieve such a feat of metallurgical engineering centuries before modern science understood the principles of corrosion resistance? The answer remains largely shrouded in mystery, leading to fascinating theories and a deep appreciation for the advanced knowledge of our ancestors.

A Pillar of Purity and Piety

Inscribed with Sanskrit verses, the pillar is believed to have been erected in the 5th century CE by Chandragupta II Vikramaditya, a powerful emperor of the Gupta dynasty. Originally dedicated to the Hindu deity Vishnu, it was likely moved to its current location in the 13th century. Its primary purpose was not just a monument, but a testament to the emperor’s victories and devotion.

The Rust Resistance Enigma

The most remarkable characteristic of the Iron Pillar is its extraordinary resistance to corrosion. While other iron artifacts from similar periods have long succumbed to rust, the pillar stands as a defiant testament to ancient ingenuity.

Scientific analysis has revealed some fascinating clues. The pillar is composed of 99.72% pure wrought iron, a remarkable achievement for its time. What truly sets it apart, however, is the presence of a thin, passive protective layer of “misawite,” a compound formed from iron, oxygen, and hydrogen. This layer acts as a barrier, preventing atmospheric moisture and oxygen from reaching the underlying metal and initiating the rusting process.

How Was It Made?

The creation of the Iron Pillar involved a sophisticated process known as “forge welding.” Large lumps of hot, wrought iron were repeatedly hammered and fused together. This meticulous and labor-intensive technique likely introduced the impurities that, paradoxically, contribute to its rust resistance. The high phosphorus content in the iron, originating from the ore used, is believed to play a crucial role in forming the protective misawite layer.

Furthermore, the specific atmospheric conditions in Delhi, characterized by dry periods and dew formation, might also contribute to the unique rust-resistant properties by facilitating the formation and reformation of this protective layer.

Beyond Our Understanding?

While modern metallurgy can analyze the pillar’s composition, replicating its rust-defying properties with the same purity and on such a large scale, using ancient techniques, remains an immense challenge. This leads many to ponder: did ancient Indian metallurgists possess an intuitive understanding of material science that went beyond mere empirical observation? Were they aware of the specific properties of the ores they used and the conditions necessary to create such a durable material?

The Iron Pillar of Delhi stands as a humbling reminder of the advanced scientific and engineering capabilities that flourished in ancient civilizations. It challenges our contemporary assumptions about technological progress and invites us to look with renewed awe at the ingenuity of our ancestors, whose “rust-defying” legacy continues to inspire wonder and scientific inquiry.

Usain Bolt: Sprinting Legend & Global Inspiration

Rajiv Gandhi Assassination Explained : Full Story Covered